Introduction [1]

We can print on many substrates including wood, metal and plastics and yet the most important medium we print on is paper. There is one mill that has been historically aligned with the development of the printing process and that is St Cuthberts Mill in Wells, Somerset, England.

The mill is on the edge of the ancient cathedral city of Wells and is named after the local church dedicated to the the seventh century saint. The St Cuthbert's Cross illustrated on the mills artist paper in inspired by the cross on St Cuthbert's tomb in Durham Cathedral.

St Cuthbert's Cross illustrated on the mill's artist paper.

St Cuthberts Mill after the extension of 1889 to 1897.

St Cuthberts Mill as it appears today.

The mill has been active since the 1700s and is the only mill in the UK that makes artist paper. Somerset paper is of premium quality and is the printmakers choice across the globe. The mill is well placed being near the source of the River Axe, with its pure water filtered through the limestone of Mendip Hills.

Paper making requires a supply of clean water and all paper mills are located on/near a water source.

The River Axe, with its pure water filtered through the limestone of Mendip Hills.

Nearly four hundred years ago, paper making started in the Axe Valley at Wookey Hole. More than two hundred years ago papermaking started on the St Cuthbert site. St Cuthbert Mill is the only surviving paper mill our of the six once operating in the upper Axe Valley.

The first stage of papermaking at St Cuthberts Mill is the filtration of the water through large, historic sand filters. These filters clear any debris from the river water. Heavy rain means that more silt is brought into the system thereby affecting the production of white paper that is so sought after by artists who want to use this quality paper.

The filtered water gets pumped into a huge vat, or hydrapulper, along with 200 kg blocks of cotton linters, which is pulped into a porridge like mixture called 'stuff'. The stuff is collected on to a spinning cylinder complete with custom watermarks and fed by hand through a cylinder mould between two felts, giving the paper its signature texture. Each roller has two strips of paper in production at the same time, sectioned off by tape; this gives the paper its beautiful deckle edge.

The paper is dried to cure the sizing agent (which controls absorbency), then it is wetted again and dried again, this time being left to retain slight moisture. The paper is digitally measured to test that the weight is equal across the sheet before it comes off the press. Each batch of paper produced undergoes a series of strict control measures to make sure the paper is produced to the same standard every time.

Paper production schematic.

Paper production on rollers.

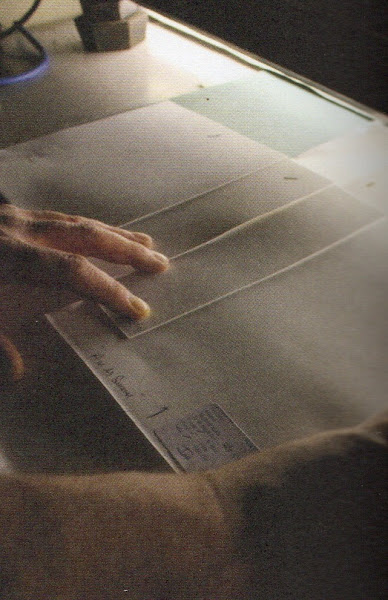

Hand checking fine-art paper.

Fine art paper.

Timelines of Paper Making: 1736 - 2010

Year 1736: Handmade paper production starts on the Cuthberts site under the name Lower Wookey Mill →Year 1835: First papermaking machine installed.→Year 1850: Present frontage of mill is built using local stone.→Year 1862: The mill is renamed Mendip Mill, in honor of the local hills.→Year 1887: The mill is renamed again as St Cuthberts Mill, after the parish of the local church inn which it is situated.→Year 1897: Office building built.→Year 1899: Somerset watermark first used for writing paper.→Year 1907: Cylinder mould machine (still used to make artist papers) built.→Year 1927: St Cuthberts Mill becomes a major shareholder in Scottish paper manufacturer Inveresk.→Year 1931: St Cuthberts Mill is bought by Inveresk.→Year 1950: Inveresk buys nearby Wookey Hole Mill (first established in 1425).→Year 1952: Cylinder mould machine installed at Wookey Hole.→Year 1957: Current PM1 paper machine installed.→Year 1957: 'Melamon' resin-loaded board first developed at Wookey Hole Mill.→Year 1959: Wookey Hole purchases the rights to produce T.H. Saunders paper (originally developed in 1920). →Year 1972: Wookey Hole Mill sold (now a tourist attraction) and the mould machine transferred to St Cuthberts Mill. Watercolor paper production now solely made at St Cuthberts Mill (including handmade, which will continue until 1976).→Year 1975: Bockingford rights purchased from Whatman.→Year 1976: Somerset traditional printmaking paper developed and launched.→Year 1981: Inveresk, including St Cuthberts Mill, is sold to Georgia Pacific and becomes GP Inveresk.→Year 1985: T.H. Saunders is developed to improve the surface strength of the paper.→Year 1990: Inveresk is sold by Georgia Pacific in a management buyout.→Year 1991: Three million pound investment in PM1 for pre-impregnated paper.→Year 1993: Inveresk floated on the Stock Exchange.→Year 1994: Somerset Velvet Radiant White developed and launched, creating an uncoated injet paper without the dot grain associated with uncoated papers.→Year 1999: Fine art inkjet papers developed and Somerset Enhanced launched.→Year 2002: Bockingford Inkjet launched.→Year 2007: Somerset Photo launched.→Year 2010: St Cuthberts Mill Ltd created.

Reference:

[1] M.Smith, People of Print, Thames & Hudson, London (2017).

We can print on many substrates including wood, metal and plastics and yet the most important medium we print on is paper. There is one mill that has been historically aligned with the development of the printing process and that is St Cuthberts Mill in Wells, Somerset, England.

The mill is on the edge of the ancient cathedral city of Wells and is named after the local church dedicated to the the seventh century saint. The St Cuthbert's Cross illustrated on the mills artist paper in inspired by the cross on St Cuthbert's tomb in Durham Cathedral.

St Cuthbert's Cross illustrated on the mill's artist paper.

St Cuthberts Mill after the extension of 1889 to 1897.

St Cuthberts Mill as it appears today.

The mill has been active since the 1700s and is the only mill in the UK that makes artist paper. Somerset paper is of premium quality and is the printmakers choice across the globe. The mill is well placed being near the source of the River Axe, with its pure water filtered through the limestone of Mendip Hills.

Paper making requires a supply of clean water and all paper mills are located on/near a water source.

The River Axe, with its pure water filtered through the limestone of Mendip Hills.

Nearly four hundred years ago, paper making started in the Axe Valley at Wookey Hole. More than two hundred years ago papermaking started on the St Cuthbert site. St Cuthbert Mill is the only surviving paper mill our of the six once operating in the upper Axe Valley.

The first stage of papermaking at St Cuthberts Mill is the filtration of the water through large, historic sand filters. These filters clear any debris from the river water. Heavy rain means that more silt is brought into the system thereby affecting the production of white paper that is so sought after by artists who want to use this quality paper.

The filtered water gets pumped into a huge vat, or hydrapulper, along with 200 kg blocks of cotton linters, which is pulped into a porridge like mixture called 'stuff'. The stuff is collected on to a spinning cylinder complete with custom watermarks and fed by hand through a cylinder mould between two felts, giving the paper its signature texture. Each roller has two strips of paper in production at the same time, sectioned off by tape; this gives the paper its beautiful deckle edge.

The paper is dried to cure the sizing agent (which controls absorbency), then it is wetted again and dried again, this time being left to retain slight moisture. The paper is digitally measured to test that the weight is equal across the sheet before it comes off the press. Each batch of paper produced undergoes a series of strict control measures to make sure the paper is produced to the same standard every time.

Paper production schematic.

Paper production on rollers.

Hand checking fine-art paper.

Fine art paper.

Timelines of Paper Making: 1736 - 2010

Year 1736: Handmade paper production starts on the Cuthberts site under the name Lower Wookey Mill →Year 1835: First papermaking machine installed.→Year 1850: Present frontage of mill is built using local stone.→Year 1862: The mill is renamed Mendip Mill, in honor of the local hills.→Year 1887: The mill is renamed again as St Cuthberts Mill, after the parish of the local church inn which it is situated.→Year 1897: Office building built.→Year 1899: Somerset watermark first used for writing paper.→Year 1907: Cylinder mould machine (still used to make artist papers) built.→Year 1927: St Cuthberts Mill becomes a major shareholder in Scottish paper manufacturer Inveresk.→Year 1931: St Cuthberts Mill is bought by Inveresk.→Year 1950: Inveresk buys nearby Wookey Hole Mill (first established in 1425).→Year 1952: Cylinder mould machine installed at Wookey Hole.→Year 1957: Current PM1 paper machine installed.→Year 1957: 'Melamon' resin-loaded board first developed at Wookey Hole Mill.→Year 1959: Wookey Hole purchases the rights to produce T.H. Saunders paper (originally developed in 1920). →Year 1972: Wookey Hole Mill sold (now a tourist attraction) and the mould machine transferred to St Cuthberts Mill. Watercolor paper production now solely made at St Cuthberts Mill (including handmade, which will continue until 1976).→Year 1975: Bockingford rights purchased from Whatman.→Year 1976: Somerset traditional printmaking paper developed and launched.→Year 1981: Inveresk, including St Cuthberts Mill, is sold to Georgia Pacific and becomes GP Inveresk.→Year 1985: T.H. Saunders is developed to improve the surface strength of the paper.→Year 1990: Inveresk is sold by Georgia Pacific in a management buyout.→Year 1991: Three million pound investment in PM1 for pre-impregnated paper.→Year 1993: Inveresk floated on the Stock Exchange.→Year 1994: Somerset Velvet Radiant White developed and launched, creating an uncoated injet paper without the dot grain associated with uncoated papers.→Year 1999: Fine art inkjet papers developed and Somerset Enhanced launched.→Year 2002: Bockingford Inkjet launched.→Year 2007: Somerset Photo launched.→Year 2010: St Cuthberts Mill Ltd created.

Reference:

[1] M.Smith, People of Print, Thames & Hudson, London (2017).

No comments:

Post a Comment