Preamble

This is the ninety-fourth post in the "Art Resource" series, specifically aimed to construct an appropriate knowledge base in order to develop an artistic voice in ArtCloth.

Other posts in this series are:

Glossary of Cultural and Architectural Terms

Units Used in Dyeing and Printing of Fabrics

Occupational, Health & Safety

A Brief History of Color

The Nature of Color

Psychology of Color

Color Schemes

The Naming of Colors

The Munsell Color Classification System

Methuen Color Index and Classification System

The CIE System

Pantone - A Modern Color Classification System

Optical Properties of Fiber Materials

General Properties of Fiber Polymers and Fibers - Part I

General Properties of Fiber Polymers and Fibers - Part II

General Properties of Fiber Polymers and Fibers - Part III

General Properties of Fiber Polymers and Fibers - Part IV

General Properties of Fiber Polymers and Fibers - Part V

Protein Fibers - Wool

Protein Fibers - Speciality Hair Fibers

Protein Fibers - Silk

Protein Fibers - Wool versus Silk

Timelines of Fabrics, Dyes and Other Stuff

Cellulosic Fibers (Natural) - Cotton

Cellulosic Fibers (Natural) - Linen

Other Natural Cellulosic Fibers

General Overview of Man-Made Fibers

Man-Made Cellulosic Fibers - Viscose

Man-Made Cellulosic Fibers - Esters

Man-Made Synthetic Fibers - Nylon

Man-Made Synthetic Fibers - Polyester

Man-Made Synthetic Fibers - Acrylic and Modacrylic

Man-Made Synthetic Fibers - Olefins

Man-Made Synthetic Fibers - Elastomers

Man-Made Synthetic Fibers - Mineral Fibers

Man Made Fibers - Other Textile Fibers

Fiber Blends

From Fiber to Yarn: Overview - Part I

From Fiber to Yarn: Overview - Part II

Melt-Spun Fibers

Characteristics of Filament Yarn

Yarn Classification

Direct Spun Yarns

Textured Filament Yarns

Fabric Construction - Felt

Fabric Construction - Nonwoven fabrics

A Fashion Data Base

Fabric Construction - Leather

Fabric Construction - Films

Glossary of Colors, Dyes, Inks, Pigments and Resins

Fabric Construction – Foams and Poromeric Material

Knitting

Hosiery

Glossary of Fabrics, Fibers, Finishes, Garments and Yarns

Weaving and the Loom

Similarities and Differences in Woven Fabrics

The Three Basic Weaves - Plain Weave (Part I)

The Three Basic Weaves - Plain Weave (Part II)

The Three Basic Weaves - Twill Weave

The Three Basic Weaves - Satin Weave

Figured Weaves - Leno Weave

Figured Weaves – Piqué Weave

Figured Fabrics

Glossary of Art, Artists, Art Motifs and Art Movements

Crêpe Fabrics

Crêpe Effect Fabrics

Pile Fabrics - General

Woven Pile Fabrics

Chenille Yarn and Tufted Pile Fabrics

Knit-Pile Fabrics

Flocked Pile Fabrics and Other Pile Construction Processes

Glossary of Paper, Photography, Printing, Prints and Publication Terms

Napped Fabrics – Part I

Napped Fabrics – Part II

Double Cloth

Multicomponent Fabrics

Knit-Sew or Stitch Through Fabrics

Finishes - Overview

Finishes - Initial Fabric Cleaning

Mechanical Finishes - Part I

Mechanical Finishes - Part II

Additive Finishes

Chemical Finishes - Bleaching

Glossary of Scientific Terms

Chemical Finishes - Acid Finishes

Finishes: Mercerization

Finishes: Waterproof and Water-Repellent Fabrics

Finishes: Flame-Proofed Fabrics

Finishes to Prevent Attack by Insects and Micro-Organisms

Other Finishes

Shrinkage - Part I

Shrinkage - Part II

Progressive Shrinkage and Methods of Control

Durable Press and Wash-and-Wear Finishes - Part I

Durable Press and Wash-and-Wear Finishes - Part II

Durable Press and Wash-and-Wear Finishes - Part III

Durable Press and Wash-and-Wear Finishes - Part IV

Durable Press and Wash-and-Wear Finishes - Part V

The General Theory of Dyeing – Part I

The General Theory Of Dyeing - Part II

Natural Dyes

Natural Dyes - Indigo

Mordant Dyes

Premetallized Dyes

Azoic Dyes

Basic Dyes

Acid Dyes

Disperse Dyes

Direct Dyes

Reactive Dyes

Sulfur Dyes

Blends – Fibers and Direct Dyeing

The General Theory of Printing

There are currently eight data bases on this blogspot, namely, the Glossary of Cultural and Architectural Terms, Timelines of Fabrics, Dyes and Other Stuff, A Fashion Data Base, the Glossary of Colors, Dyes, Inks, Pigments and Resins, the Glossary of Fabrics, Fibers, Finishes, Garments and Yarns, Glossary of Art, Artists, Art Motifs and Art Movements, Glossary of Paper, Photography, Printing, Prints and Publication Terms and the Glossary of Scientific Terms, which has been updated to Version 3.5. All data bases will be updated from time-to-time in the future.

If you find any post on this blog site useful, you can save it or copy and paste it into your own "Word" document etc. for your future reference. For example, Safari allows you to save a post (e.g. click on "File", click on "Print" and release, click on "PDF" and then click on "Save As" and release - and a PDF should appear where you have stored it). Safari also allows you to mail a post to a friend (click on "File", and then point cursor to "Mail Contents On This Page" and release). Either way, this or other posts on this site may be a useful Art Resource for you.

The Art Resource series will be the first post in each calendar month. Remember - these Art Resource posts span information that will be useful for a home hobbyist to that required by a final year University Fine-Art student and so undoubtedly, some parts of any Art Resource post may appear far too technical for your needs (skip over those mind boggling parts) and in other parts, it may be too simplistic with respect to your level of knowledge (ditto the skip). The trade-off between these two extremes will mean that Art Resource posts will hopefully be useful in parts to most, but unfortunately may not be satisfying to all!

Durable Press and Wash-and-Wear Finishes - Part II[1]

Wash-and-Wear Versus Durable Press

The conventional wash-and-wear finish was designed to set flat fabric so that it would retain a smooth unwrinkled condition. On the other hand, durable press has been described as the mature, more sophisticated heir to wash-and-wear garments. It was designed to set the shape of the garment.

There have been two theories concerning the function of the resins in the fiber. The deposition theory was that the resin filled up space within the fiber to prevent the penetration of moisture and keep the fiber from swelling when it became wet. The cross-linking theory, accepted about 1948, was that the resin or reactant formed cross-links between the molecular chains to tie them together and limit chain slippage.

Finishing Agents

A continuing research program by industry - particularly the cotton industry - has resulted in the development of many: (i) new resins and reactants; (ii) better processes to improve continually the performance of wash-and-wear finishes available to the consumer.

Whitening Softener HR-600.

Mainly used for cotton, polyester/cotton bleaching and whitening textile softening.

Main composition is hydroxy silicone.

The finish usually contains more than the resin or reactant. Some of the other substances are: catalysts, silicone emulsion softeners, optical whiteners, and thermoplastic polymers.

Mercerizing Smoothing Agent 3162C. This product is dedicated to polyester, polyester superfine, mercerized yarn, garment mercerizing treatment of fabric.

Resins are a family of chemical that can be applied to cotton, rayon, and linen fabrics in monomer form.

PP Resin for nonwoven fabrics.

They will polymerise when heat cured to firm cross-links between the molecular chassis of cellulose. The formaldehyde resins have been known for ~ 110 years and have been used for about the last 80 years. One dated method - the vapour phase method - uses formaldehyde resins.

A process of treating a textile fabric containing cellulosic fibers to impart crease resistance in which the fabric is impregnated with an aqueous solution containing formaldehyde and a curing catalyst, vacuum is applied to the impregnated fabric to remove excess impregnation solution and to provide a wet pickup of about 15 to 35 percent, and the fabric is then dried and cured.

Phenol formaldehyde was the first to be used, but it was discarded because it discoloured the cloth. Urea formaldehyde for rayon and melamine formaldehyde for cotton were the first to be used successfully. Many resins have been tried and discarded because of poor resistance to conditions of use or for lack of permanence to washing. The nitrogen-containing resins could not be used on white fabrics because of yellowing when bleached with chlorine.

Phenolic yellowing of textile.

Cellulose reactants are non resinous chemicals that have a definite chemical reaction with the cellulose fiber polymer. The aldehydes and sulfones are examples of these. Cellulose reactants have been described as:"...an effective way to impart crease recovery to cellulose fabrics by establishing covalent bonds between the molecule and the individual fiber[1].

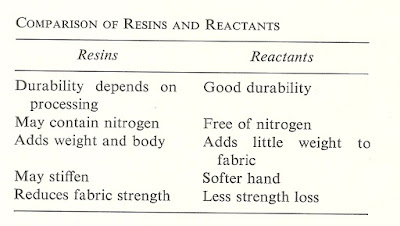

Below is a table that compares some resins and reactants.

Reference:

[1] N. Hollen and J. Saddler, Textiles, 3rd Edition, MacMillan Company, London (1968).

This is the ninety-fourth post in the "Art Resource" series, specifically aimed to construct an appropriate knowledge base in order to develop an artistic voice in ArtCloth.

Other posts in this series are:

Glossary of Cultural and Architectural Terms

Units Used in Dyeing and Printing of Fabrics

Occupational, Health & Safety

A Brief History of Color

The Nature of Color

Psychology of Color

Color Schemes

The Naming of Colors

The Munsell Color Classification System

Methuen Color Index and Classification System

The CIE System

Pantone - A Modern Color Classification System

Optical Properties of Fiber Materials

General Properties of Fiber Polymers and Fibers - Part I

General Properties of Fiber Polymers and Fibers - Part II

General Properties of Fiber Polymers and Fibers - Part III

General Properties of Fiber Polymers and Fibers - Part IV

General Properties of Fiber Polymers and Fibers - Part V

Protein Fibers - Wool

Protein Fibers - Speciality Hair Fibers

Protein Fibers - Silk

Protein Fibers - Wool versus Silk

Timelines of Fabrics, Dyes and Other Stuff

Cellulosic Fibers (Natural) - Cotton

Cellulosic Fibers (Natural) - Linen

Other Natural Cellulosic Fibers

General Overview of Man-Made Fibers

Man-Made Cellulosic Fibers - Viscose

Man-Made Cellulosic Fibers - Esters

Man-Made Synthetic Fibers - Nylon

Man-Made Synthetic Fibers - Polyester

Man-Made Synthetic Fibers - Acrylic and Modacrylic

Man-Made Synthetic Fibers - Olefins

Man-Made Synthetic Fibers - Elastomers

Man-Made Synthetic Fibers - Mineral Fibers

Man Made Fibers - Other Textile Fibers

Fiber Blends

From Fiber to Yarn: Overview - Part I

From Fiber to Yarn: Overview - Part II

Melt-Spun Fibers

Characteristics of Filament Yarn

Yarn Classification

Direct Spun Yarns

Textured Filament Yarns

Fabric Construction - Felt

Fabric Construction - Nonwoven fabrics

A Fashion Data Base

Fabric Construction - Leather

Fabric Construction - Films

Glossary of Colors, Dyes, Inks, Pigments and Resins

Fabric Construction – Foams and Poromeric Material

Knitting

Hosiery

Glossary of Fabrics, Fibers, Finishes, Garments and Yarns

Weaving and the Loom

Similarities and Differences in Woven Fabrics

The Three Basic Weaves - Plain Weave (Part I)

The Three Basic Weaves - Plain Weave (Part II)

The Three Basic Weaves - Twill Weave

The Three Basic Weaves - Satin Weave

Figured Weaves - Leno Weave

Figured Weaves – Piqué Weave

Figured Fabrics

Glossary of Art, Artists, Art Motifs and Art Movements

Crêpe Fabrics

Crêpe Effect Fabrics

Pile Fabrics - General

Woven Pile Fabrics

Chenille Yarn and Tufted Pile Fabrics

Knit-Pile Fabrics

Flocked Pile Fabrics and Other Pile Construction Processes

Glossary of Paper, Photography, Printing, Prints and Publication Terms

Napped Fabrics – Part I

Napped Fabrics – Part II

Double Cloth

Multicomponent Fabrics

Knit-Sew or Stitch Through Fabrics

Finishes - Overview

Finishes - Initial Fabric Cleaning

Mechanical Finishes - Part I

Mechanical Finishes - Part II

Additive Finishes

Chemical Finishes - Bleaching

Glossary of Scientific Terms

Chemical Finishes - Acid Finishes

Finishes: Mercerization

Finishes: Waterproof and Water-Repellent Fabrics

Finishes: Flame-Proofed Fabrics

Finishes to Prevent Attack by Insects and Micro-Organisms

Other Finishes

Shrinkage - Part I

Shrinkage - Part II

Progressive Shrinkage and Methods of Control

Durable Press and Wash-and-Wear Finishes - Part I

Durable Press and Wash-and-Wear Finishes - Part II

Durable Press and Wash-and-Wear Finishes - Part III

Durable Press and Wash-and-Wear Finishes - Part IV

Durable Press and Wash-and-Wear Finishes - Part V

The General Theory of Dyeing – Part I

The General Theory Of Dyeing - Part II

Natural Dyes

Natural Dyes - Indigo

Mordant Dyes

Premetallized Dyes

Azoic Dyes

Basic Dyes

Acid Dyes

Disperse Dyes

Direct Dyes

Reactive Dyes

Sulfur Dyes

Blends – Fibers and Direct Dyeing

The General Theory of Printing

There are currently eight data bases on this blogspot, namely, the Glossary of Cultural and Architectural Terms, Timelines of Fabrics, Dyes and Other Stuff, A Fashion Data Base, the Glossary of Colors, Dyes, Inks, Pigments and Resins, the Glossary of Fabrics, Fibers, Finishes, Garments and Yarns, Glossary of Art, Artists, Art Motifs and Art Movements, Glossary of Paper, Photography, Printing, Prints and Publication Terms and the Glossary of Scientific Terms, which has been updated to Version 3.5. All data bases will be updated from time-to-time in the future.

If you find any post on this blog site useful, you can save it or copy and paste it into your own "Word" document etc. for your future reference. For example, Safari allows you to save a post (e.g. click on "File", click on "Print" and release, click on "PDF" and then click on "Save As" and release - and a PDF should appear where you have stored it). Safari also allows you to mail a post to a friend (click on "File", and then point cursor to "Mail Contents On This Page" and release). Either way, this or other posts on this site may be a useful Art Resource for you.

The Art Resource series will be the first post in each calendar month. Remember - these Art Resource posts span information that will be useful for a home hobbyist to that required by a final year University Fine-Art student and so undoubtedly, some parts of any Art Resource post may appear far too technical for your needs (skip over those mind boggling parts) and in other parts, it may be too simplistic with respect to your level of knowledge (ditto the skip). The trade-off between these two extremes will mean that Art Resource posts will hopefully be useful in parts to most, but unfortunately may not be satisfying to all!

Durable Press and Wash-and-Wear Finishes - Part II[1]

Wash-and-Wear Versus Durable Press

The conventional wash-and-wear finish was designed to set flat fabric so that it would retain a smooth unwrinkled condition. On the other hand, durable press has been described as the mature, more sophisticated heir to wash-and-wear garments. It was designed to set the shape of the garment.

There have been two theories concerning the function of the resins in the fiber. The deposition theory was that the resin filled up space within the fiber to prevent the penetration of moisture and keep the fiber from swelling when it became wet. The cross-linking theory, accepted about 1948, was that the resin or reactant formed cross-links between the molecular chains to tie them together and limit chain slippage.

Finishing Agents

A continuing research program by industry - particularly the cotton industry - has resulted in the development of many: (i) new resins and reactants; (ii) better processes to improve continually the performance of wash-and-wear finishes available to the consumer.

Whitening Softener HR-600.

Mainly used for cotton, polyester/cotton bleaching and whitening textile softening.

Main composition is hydroxy silicone.

The finish usually contains more than the resin or reactant. Some of the other substances are: catalysts, silicone emulsion softeners, optical whiteners, and thermoplastic polymers.

Mercerizing Smoothing Agent 3162C. This product is dedicated to polyester, polyester superfine, mercerized yarn, garment mercerizing treatment of fabric.

Resins are a family of chemical that can be applied to cotton, rayon, and linen fabrics in monomer form.

PP Resin for nonwoven fabrics.

They will polymerise when heat cured to firm cross-links between the molecular chassis of cellulose. The formaldehyde resins have been known for ~ 110 years and have been used for about the last 80 years. One dated method - the vapour phase method - uses formaldehyde resins.

A process of treating a textile fabric containing cellulosic fibers to impart crease resistance in which the fabric is impregnated with an aqueous solution containing formaldehyde and a curing catalyst, vacuum is applied to the impregnated fabric to remove excess impregnation solution and to provide a wet pickup of about 15 to 35 percent, and the fabric is then dried and cured.

Phenol formaldehyde was the first to be used, but it was discarded because it discoloured the cloth. Urea formaldehyde for rayon and melamine formaldehyde for cotton were the first to be used successfully. Many resins have been tried and discarded because of poor resistance to conditions of use or for lack of permanence to washing. The nitrogen-containing resins could not be used on white fabrics because of yellowing when bleached with chlorine.

Phenolic yellowing of textile.

Cellulose reactants are non resinous chemicals that have a definite chemical reaction with the cellulose fiber polymer. The aldehydes and sulfones are examples of these. Cellulose reactants have been described as:"...an effective way to impart crease recovery to cellulose fabrics by establishing covalent bonds between the molecule and the individual fiber[1].

Below is a table that compares some resins and reactants.

Reference:

[1] N. Hollen and J. Saddler, Textiles, 3rd Edition, MacMillan Company, London (1968).

No comments:

Post a Comment