Preamble

This is the sixty-ninth post in the "Art Resource" series, specifically aimed to construct an appropriate knowledge base in order to develop an artistic voice in ArtCloth.

Other posts in this series are:

Glossary of Cultural and Architectural Terms

Units Used in Dyeing and Printing of Fabrics

Occupational, Health & Safety

A Brief History of Color

The Nature of Color

Psychology of Color

Color Schemes

The Naming of Colors

The Munsell Color Classification System

Methuen Color Index and Classification System

The CIE System

Pantone - A Modern Color Classification System

Optical Properties of Fiber Materials

General Properties of Fiber Polymers and Fibers - Part I

General Properties of Fiber Polymers and Fibers - Part II

General Properties of Fiber Polymers and Fibers - Part III

General Properties of Fiber Polymers and Fibers - Part IV

General Properties of Fiber Polymers and Fibers - Part V

Protein Fibers - Wool

Protein Fibers - Speciality Hair Fibers

Protein Fibers - Silk

Protein Fibers - Wool versus Silk

Timelines of Fabrics, Dyes and Other Stuff

Cellulosic Fibers (Natural) - Cotton

Cellulosic Fibers (Natural) - Linen

Other Natural Cellulosic Fibers

General Overview of Man-Made Fibers

Man-Made Cellulosic Fibers - Viscose

Man-Made Cellulosic Fibers - Esters

Man-Made Synthetic Fibers - Nylon

Man-Made Synthetic Fibers - Polyester

Man-Made Synthetic Fibers - Acrylic and Modacrylic

Man-Made Synthetic Fibers - Olefins

Man-Made Synthetic Fibers - Elastomers

Man-Made Synthetic Fibers - Mineral Fibers

Man Made Fibers - Other Textile Fibers

Fiber Blends

From Fiber to Yarn: Overview - Part I

From Fiber to Yarn: Overview - Part II

Melt-Spun Fibers

Characteristics of Filament Yarn

Yarn Classification

Direct Spun Yarns

Textured Filament Yarns

Fabric Construction - Felt

Fabric Construction - Nonwoven fabrics

A Fashion Data Base

Fabric Construction - Leather

Fabric Construction - Films

Glossary of Colors, Dyes, Inks, Pigments and Resins

Fabric Construction – Foams and Poromeric Material

Knitting

Hosiery

Glossary of Fabrics, Fibers, Finishes, Garments and Yarns

Weaving and the Loom

Similarities and Differences in Woven Fabrics

The Three Basic Weaves - Plain Weave (Part I)

The Three Basic Weaves - Plain Weave (Part II)

The Three Basic Weaves - Twill Weave

The Three Basic Weaves - Satin Weave

Figured Weaves - Leno Weave

Figured Weaves – Piqué Weave

Figured Fabrics

Glossary of Art, Artists, Art Motifs and Art Movements

Crêpe Fabrics

Crêpe Effect Fabrics

Pile Fabrics - General

Woven Pile Fabrics

Chenille Yarn and Tufted Pile Fabrics

Knit-Pile Fabrics

Flocked Pile Fabrics and Other Pile Construction Processes

Glossary of Paper, Photography, Printing, Prints and Publication Terms

Napped Fabrics – Part I

Napped Fabrics – Part II

Double Cloth

Multicomponent Fabrics

Knit-Sew or Stitch Through Fabrics

Finishes - Overview

Finishes - Initial Fabric Cleaning

Mechanical Finishes - Part I

Mechanical Finishes - Part II

Additive Finishes

Chemical Finishes - Bleaching

Glossary of Scientific Terms

Chemical Finishes - Acid Finishes

Finishes: Mercerization

Finishes: Waterproof and Water-Repellent Fabrics

Finishes: Flame-Proofed Fabrics

Finishes to Prevent Attack by Insects and Micro-Organisms

Other Finishes

Shrinkage - Part I

Shrinkage - Part II

Progressive Shrinkage and Methods of Control

Durable Press and Wash-and-Wear Finishes - Part I

Durable Press and Wash-and-Wear Finishes - Part II

Durable Press and Wash-and-Wear Finishes - Part III

Durable Press and Wash-and-Wear Finishes - Part IV

Durable Press and Wash-and-Wear Finishes - Part V

The General Theory of Dyeing – Part I

The General Theory Of Dyeing - Part II

Natural Dyes

Natural Dyes - Indigo

Mordant Dyes

Premetallized Dyes

Azoic Dyes

Basic Dyes

Acid Dyes

Disperse Dyes

Direct Dyes

Reactive Dyes

Sulfur Dyes

Blends – Fibers and Direct Dyeing

The General Theory of Printing

There are currently eight data bases on this blogspot, namely, the Glossary of Cultural and Architectural Terms, Timelines of Fabrics, Dyes and Other Stuff, A Fashion Data Base, the Glossary of Colors, Dyes, Inks, Pigments and Resins, the Glossary of Fabrics, Fibers, Finishes, Garments and Yarns, Glossary of Art, Artists, Art Motifs and Art Movements, Glossary of Paper, Photography, Printing, Prints and Publication Terms and the Glossary of Scientific Terms, which has been updated to Version 3.5. All data bases will be updated from time-to-time in the future.

If you find any post on this blog site useful, you can save it or copy and paste it into your own "Word" document etc. for your future reference. For example, Safari allows you to save a post (e.g. click on "File", click on "Print" and release, click on "PDF" and then click on "Save As" and release - and a PDF should appear where you have stored it). Safari also allows you to mail a post to a friend (click on "File", and then point cursor to "Mail Contents On This Page" and release). Either way, this or other posts on this site may be a useful Art Resource for you.

The Art Resource series will be the first post in each calendar month. Remember - these Art Resource posts span information that will be useful for a home hobbyist to that required by a final year University Fine-Art student and so undoubtedly, some parts of any Art Resource post may appear far too technical for your needs (skip over those mind boggling parts) and in other parts, it may be too simplistic with respect to your level of knowledge (ditto the skip). The trade-off between these two extremes will mean that Art Resource posts will hopefully be useful in parts to most, but unfortunately may not be satisfying to all!

Introduction

Today’s post continues to explore pile fabrics namely chenille yarn pile fabric (woven) and tufted pile fabrics.

Chenille yarn scarf.

Chenille Yarn Pile Fabrics (Woven)

Chenille yarn is made by cutting a specially woven ladder-like fabric into warp-wise strips.

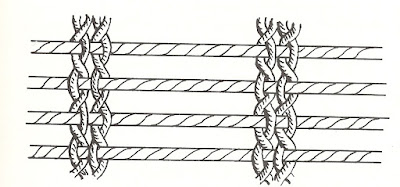

Fabric from which chenille yarn is made.

(1) Chenille yarns are made by cutting specially woven fabric. (2) Fabric made from chenille yarn.

The cut ends of softly twisted yarns loosen and form a pile-like fringe. This fringed yarn may be woven to make a fabric with pile on one or both sides. If the pile is on one side only, the yarn must be folded before it is woven. The yarn is sometimes referred to as a “caterpillar” yarn.

Cotton chenille yarn.

Tufted Pile Fabrics

Tufting is a process of making pile fabrics by punching extra yarns into an already woven fabric. The ground fabric ranges from thin cotton sheeting to heavy burlap and the pile yarns can be of any fiber content.

Tufting is the process of creating textiles, especially carpet, on specialized multi-needle sewing machines.

Tufting is a less costly method of making pile fabrics, because it is an extremely fast process and involves less labor and time to create new designs. A tufted bed-size blanket can be made in two minutes. A tufting machine can produce approximately 645 square yards of carpeting per hour compared to an Axminster loom, which can weave about 14 squre yards per hour.

Tufted acrylic blanket with satin bound edge.

Tufting developed in South Eastern of USA as a handicraft. It is said that the early settlers trimmed off wicks from their homemade candles and carefully worked them into bedspreads to create interesting textures and designs. Later, a needle was used to insert the thick yarn and the making of candlewick bedspreads grew into a cottage industry. Hooked rugs were also made by hand in the same way.

Hooked rug made in the 1930s. Predominately brown and green, it features flowers that look like poinsettias. The rug measures 35" x 58". It was hooked into burlap, tight hooks, no loose loops.

In the 1930s, machinery was developed to convert the hand technique to mass production. Cotton rugs, bedspreads and robes were produced in many patterns and colors at low cost. In 1950, the first room-width carpeting was made; by 1966, 85% of the broadloom carpeting was made by tufting.

Tufted broadloom carpet.

In 1960, Barwich Mills Inc. started pilot plant operations on tufted blankets. This end-use combines pile construction with napped finish. It has the advantage over traditional blanket fabric of maintaining a strong, firm ground fabric, since the fibers are teased from the pile yarns to create the nap. Also the thickness of the blanket is determined by the height of the pile rather than by the thickness of the yarn. Tufted blankets have not been successful in the USA but are being produced in Europe.

Tufting is done by a series of needles, each carrying yarn from a series of spools held in a creel.

Drawing illustrating the tufting process.

Tufted fabric. Notice machine like stitches on the wrong side.

The backing fabric is held in a horizontal position the needles all come down at once and go through the fabric at a predetermined distance, much as a sewing needle goes through a cloth. Under each needle is a hook that moves forward to hold the loop as the needle is retracted to cut the loop. The fabric moves forward at a predetermined rate, and the needles move down again to form another row of tufts.

The tufts are held in place by the blooming (untwisted) of the yarn and by shrinkage of the ground fabric in finishing. In carpeting, a latex coating is put on the back to help hold the tufts in place (see first figure in this section).

Variations in texture can be made by loops of different heights. Cut and uncut tufts can be combined. Tweedy textures are made by the use of different colored plys in the tufting yarns. New techniques of dying have been developed to produce colored patterns or figures in which the color penetrates the tufts completely.

Reference:

[1] N. Hollen and J. Saddler, Textiles, 3rd Edition, MacMillan Company, London (1968).

This is the sixty-ninth post in the "Art Resource" series, specifically aimed to construct an appropriate knowledge base in order to develop an artistic voice in ArtCloth.

Other posts in this series are:

Glossary of Cultural and Architectural Terms

Units Used in Dyeing and Printing of Fabrics

Occupational, Health & Safety

A Brief History of Color

The Nature of Color

Psychology of Color

Color Schemes

The Naming of Colors

The Munsell Color Classification System

Methuen Color Index and Classification System

The CIE System

Pantone - A Modern Color Classification System

Optical Properties of Fiber Materials

General Properties of Fiber Polymers and Fibers - Part I

General Properties of Fiber Polymers and Fibers - Part II

General Properties of Fiber Polymers and Fibers - Part III

General Properties of Fiber Polymers and Fibers - Part IV

General Properties of Fiber Polymers and Fibers - Part V

Protein Fibers - Wool

Protein Fibers - Speciality Hair Fibers

Protein Fibers - Silk

Protein Fibers - Wool versus Silk

Timelines of Fabrics, Dyes and Other Stuff

Cellulosic Fibers (Natural) - Cotton

Cellulosic Fibers (Natural) - Linen

Other Natural Cellulosic Fibers

General Overview of Man-Made Fibers

Man-Made Cellulosic Fibers - Viscose

Man-Made Cellulosic Fibers - Esters

Man-Made Synthetic Fibers - Nylon

Man-Made Synthetic Fibers - Polyester

Man-Made Synthetic Fibers - Acrylic and Modacrylic

Man-Made Synthetic Fibers - Olefins

Man-Made Synthetic Fibers - Elastomers

Man-Made Synthetic Fibers - Mineral Fibers

Man Made Fibers - Other Textile Fibers

Fiber Blends

From Fiber to Yarn: Overview - Part I

From Fiber to Yarn: Overview - Part II

Melt-Spun Fibers

Characteristics of Filament Yarn

Yarn Classification

Direct Spun Yarns

Textured Filament Yarns

Fabric Construction - Felt

Fabric Construction - Nonwoven fabrics

A Fashion Data Base

Fabric Construction - Leather

Fabric Construction - Films

Glossary of Colors, Dyes, Inks, Pigments and Resins

Fabric Construction – Foams and Poromeric Material

Knitting

Hosiery

Glossary of Fabrics, Fibers, Finishes, Garments and Yarns

Weaving and the Loom

Similarities and Differences in Woven Fabrics

The Three Basic Weaves - Plain Weave (Part I)

The Three Basic Weaves - Plain Weave (Part II)

The Three Basic Weaves - Twill Weave

The Three Basic Weaves - Satin Weave

Figured Weaves - Leno Weave

Figured Weaves – Piqué Weave

Figured Fabrics

Glossary of Art, Artists, Art Motifs and Art Movements

Crêpe Fabrics

Crêpe Effect Fabrics

Pile Fabrics - General

Woven Pile Fabrics

Chenille Yarn and Tufted Pile Fabrics

Knit-Pile Fabrics

Flocked Pile Fabrics and Other Pile Construction Processes

Glossary of Paper, Photography, Printing, Prints and Publication Terms

Napped Fabrics – Part I

Napped Fabrics – Part II

Double Cloth

Multicomponent Fabrics

Knit-Sew or Stitch Through Fabrics

Finishes - Overview

Finishes - Initial Fabric Cleaning

Mechanical Finishes - Part I

Mechanical Finishes - Part II

Additive Finishes

Chemical Finishes - Bleaching

Glossary of Scientific Terms

Chemical Finishes - Acid Finishes

Finishes: Mercerization

Finishes: Waterproof and Water-Repellent Fabrics

Finishes: Flame-Proofed Fabrics

Finishes to Prevent Attack by Insects and Micro-Organisms

Other Finishes

Shrinkage - Part I

Shrinkage - Part II

Progressive Shrinkage and Methods of Control

Durable Press and Wash-and-Wear Finishes - Part I

Durable Press and Wash-and-Wear Finishes - Part II

Durable Press and Wash-and-Wear Finishes - Part III

Durable Press and Wash-and-Wear Finishes - Part IV

Durable Press and Wash-and-Wear Finishes - Part V

The General Theory of Dyeing – Part I

The General Theory Of Dyeing - Part II

Natural Dyes

Natural Dyes - Indigo

Mordant Dyes

Premetallized Dyes

Azoic Dyes

Basic Dyes

Acid Dyes

Disperse Dyes

Direct Dyes

Reactive Dyes

Sulfur Dyes

Blends – Fibers and Direct Dyeing

The General Theory of Printing

There are currently eight data bases on this blogspot, namely, the Glossary of Cultural and Architectural Terms, Timelines of Fabrics, Dyes and Other Stuff, A Fashion Data Base, the Glossary of Colors, Dyes, Inks, Pigments and Resins, the Glossary of Fabrics, Fibers, Finishes, Garments and Yarns, Glossary of Art, Artists, Art Motifs and Art Movements, Glossary of Paper, Photography, Printing, Prints and Publication Terms and the Glossary of Scientific Terms, which has been updated to Version 3.5. All data bases will be updated from time-to-time in the future.

If you find any post on this blog site useful, you can save it or copy and paste it into your own "Word" document etc. for your future reference. For example, Safari allows you to save a post (e.g. click on "File", click on "Print" and release, click on "PDF" and then click on "Save As" and release - and a PDF should appear where you have stored it). Safari also allows you to mail a post to a friend (click on "File", and then point cursor to "Mail Contents On This Page" and release). Either way, this or other posts on this site may be a useful Art Resource for you.

The Art Resource series will be the first post in each calendar month. Remember - these Art Resource posts span information that will be useful for a home hobbyist to that required by a final year University Fine-Art student and so undoubtedly, some parts of any Art Resource post may appear far too technical for your needs (skip over those mind boggling parts) and in other parts, it may be too simplistic with respect to your level of knowledge (ditto the skip). The trade-off between these two extremes will mean that Art Resource posts will hopefully be useful in parts to most, but unfortunately may not be satisfying to all!

Introduction

Today’s post continues to explore pile fabrics namely chenille yarn pile fabric (woven) and tufted pile fabrics.

Chenille yarn scarf.

Chenille Yarn Pile Fabrics (Woven)

Chenille yarn is made by cutting a specially woven ladder-like fabric into warp-wise strips.

Fabric from which chenille yarn is made.

(1) Chenille yarns are made by cutting specially woven fabric. (2) Fabric made from chenille yarn.

The cut ends of softly twisted yarns loosen and form a pile-like fringe. This fringed yarn may be woven to make a fabric with pile on one or both sides. If the pile is on one side only, the yarn must be folded before it is woven. The yarn is sometimes referred to as a “caterpillar” yarn.

Cotton chenille yarn.

Tufted Pile Fabrics

Tufting is a process of making pile fabrics by punching extra yarns into an already woven fabric. The ground fabric ranges from thin cotton sheeting to heavy burlap and the pile yarns can be of any fiber content.

Tufting is the process of creating textiles, especially carpet, on specialized multi-needle sewing machines.

Tufting is a less costly method of making pile fabrics, because it is an extremely fast process and involves less labor and time to create new designs. A tufted bed-size blanket can be made in two minutes. A tufting machine can produce approximately 645 square yards of carpeting per hour compared to an Axminster loom, which can weave about 14 squre yards per hour.

Tufted acrylic blanket with satin bound edge.

Tufting developed in South Eastern of USA as a handicraft. It is said that the early settlers trimmed off wicks from their homemade candles and carefully worked them into bedspreads to create interesting textures and designs. Later, a needle was used to insert the thick yarn and the making of candlewick bedspreads grew into a cottage industry. Hooked rugs were also made by hand in the same way.

Hooked rug made in the 1930s. Predominately brown and green, it features flowers that look like poinsettias. The rug measures 35" x 58". It was hooked into burlap, tight hooks, no loose loops.

In the 1930s, machinery was developed to convert the hand technique to mass production. Cotton rugs, bedspreads and robes were produced in many patterns and colors at low cost. In 1950, the first room-width carpeting was made; by 1966, 85% of the broadloom carpeting was made by tufting.

Tufted broadloom carpet.

In 1960, Barwich Mills Inc. started pilot plant operations on tufted blankets. This end-use combines pile construction with napped finish. It has the advantage over traditional blanket fabric of maintaining a strong, firm ground fabric, since the fibers are teased from the pile yarns to create the nap. Also the thickness of the blanket is determined by the height of the pile rather than by the thickness of the yarn. Tufted blankets have not been successful in the USA but are being produced in Europe.

Tufting is done by a series of needles, each carrying yarn from a series of spools held in a creel.

Drawing illustrating the tufting process.

Tufted fabric. Notice machine like stitches on the wrong side.

The backing fabric is held in a horizontal position the needles all come down at once and go through the fabric at a predetermined distance, much as a sewing needle goes through a cloth. Under each needle is a hook that moves forward to hold the loop as the needle is retracted to cut the loop. The fabric moves forward at a predetermined rate, and the needles move down again to form another row of tufts.

The tufts are held in place by the blooming (untwisted) of the yarn and by shrinkage of the ground fabric in finishing. In carpeting, a latex coating is put on the back to help hold the tufts in place (see first figure in this section).

Variations in texture can be made by loops of different heights. Cut and uncut tufts can be combined. Tweedy textures are made by the use of different colored plys in the tufting yarns. New techniques of dying have been developed to produce colored patterns or figures in which the color penetrates the tufts completely.

Reference:

[1] N. Hollen and J. Saddler, Textiles, 3rd Edition, MacMillan Company, London (1968).

No comments:

Post a Comment